Introduction

Bulk Liquid Cargo (BLC) shortage claims for alleged short delivery continue to present a costly risk challenge for tanker Members. Effective shortage control and loss prevention demands close attention to both ship and shore BLC measurement accuracy. This Risk Bulletin reviews the BLC measurement process for petroleum and chemical cargoes and makes recommendations to Members on the utilisation of industry ‘best practice’ standards.

NOTE: The BLC Measurement and Sampling Processes are normally accomplished together. This RB should therefore be considered and applied together with RB 64 BLC Contamination and the ‘Million Dollar Sample’.

Background

The primary contractual obligation of all tanker owners and crew is to ensure that the cargo loaded is delivered to the named discharge port in the same quantity and condition as received on board. If it is not, then – subject to the CP and/or BL contract terms – a short delivery claim will likely be brought by cargo interests against the tanker owner.

A BLC shortage claim can arise due to either ‘physical’ (actual) or ‘paper’ (apparent) losses, or both:

- ‘Physical’ losses of petroleum and chemical cargoes, often referred to as In Transit Loss (ITL), can occur as a result of cargo tank or line leakage, in transit evaporation of light faction cargo, or theft. The difficulty of pumping all shipboard cargo tanks perfectly dry is also a recognised issue.

- ‘Paper’ losses from cargo measurement error caused by human element factors, measuring equipment deficiencies and tank calibration inaccuracies. ‘Paper’ losses are very common and therefore comprise the most substantial shortage cause risk.

The intrinsic causes of BLC shortage loss and the difficulty of eliminating them have led to the petroleum industry’s creation and general acceptance of the ‘Customary Trade Allowance’ (CTA) of 0.5% of the shipper’s BL declared cargo quantity. The intended result being that any BLC shortage (due to ‘physical’ and/or ‘paper’ losses) of 0.5% or less will normally be considered as being within cargo delivery tolerance and no claim will arise.

NOTE: The CTA may be implied into CP and BL terms by many courts and arbitration panels. However, the CTA 0.5% defence is neither certain nor legally binding unless the CTA is contractually pre-agreed by the parties involved (at either 0.5% or another amount considered realistic) and is clearly stated as being applicable to both the CP and BL terms. Members should always ensure specific CTA agreement.

BLC Industry ‘Best Practice’ Guidelines and Standards

Industry BLC marine measurement standards have been developed jointly by the American Petroleum Institute (API) in the USA and the Energy Institute in London. They are published as API MPMS Chapter 17 which provides 14 very detailed standards (from Chapter 17.1 through to Chapter 17.14) for BLC crude oil, petroleum, gas and chemical cargo measurement and sampling.

The starting point is Chapter 17.1 Guidelines for Marine Inspection which contains a helpful overview of all 14 of the Chapter 17 Standards. Chapter 17.1 consists of 21 pages of text and 24 pages of sample forms, inclusive of EXCEL spreadsheets to assist data checking and quantity reconciliation. It is available at a cost of USD 150.00 from API at the link provided, as well as from technical booksellers, in either PDF or hardcopy versions.

The other Chapters, for example, Chapter 17.2 Measurement of Cargoes on Board Tank Vessels, Chapter 17.4 Method for Quantification of Small Volumes on Marine Vessels (OBQ/ROB), Chapter 17.8 Guidelines for Pre-loading Inspection of Marine Vessel Cargo Tanks, etc. are available as separate API publications. They should be obtained as may be relevant to a particular tanker’s design and trade.

MM recommends that a copy of the API Chapter 17.1 Guidelines and all other relevant API MPMS Chapter 17 Chapters should be purchased by tanker Members and made readily accessible to their tanker managers, DPAs, masters and crews. The Chapter 17.1 Guidelines and all other relevant Chapters should also be incorporated by specific reference into all tanker ISM Code or NCVS SMS manuals and procedures.

BLC Measurement Fundamentals

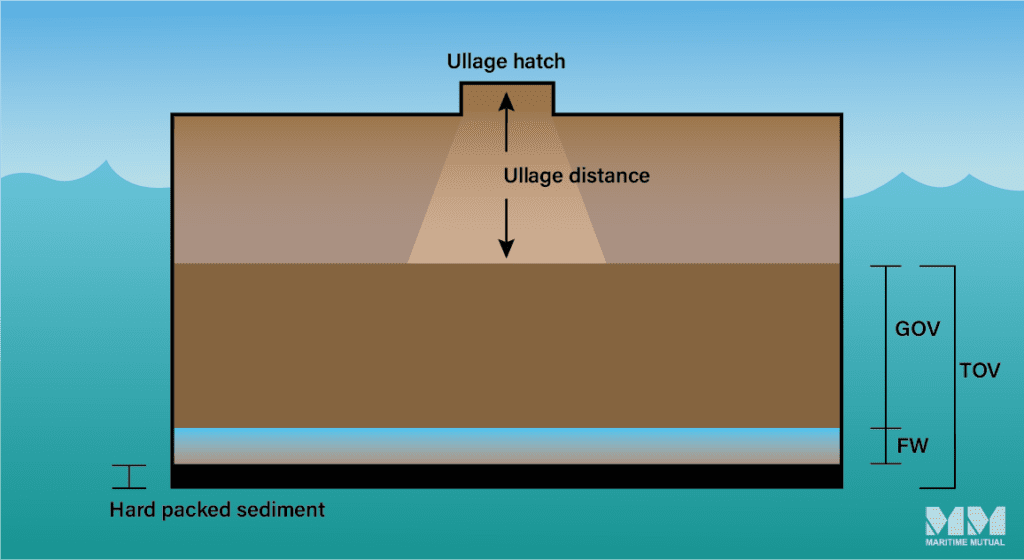

The measurement of BLC petroleum and chemicals on board tankers and in shore tanks is usually accomplished by measuring the distance (ullage) from the top of an ullage standpipe or ullage hatch of known height down to the surface level of the BLC. This distance is known as the ‘ullage’.

Measurement Terminology

The ullage measurement is used to enter a set of pre-calculated tank volume quantity tables supplied by the shipbuilder or shore tank constructor. These tables provide the Total Observed Volume (TOV) in cubic metres of the BLC – inclusive of cargo, free water (FW), entrained sediment and water (S&W) and bottom sediment – in each cargo tank at the BLC’s observed temperature as measured by a thermometer.

The TOV, less the measured FW and bottom sediment, provides the Gross Observed Volume (GOV) at the observed temperature. The GOV is then converted to Gross Standard Volume (GSV). This is done by using the ASTM Standard Guide for Petroleum Measurement, Table 53A or 53B, to obtain the Volume Correction Factor (VCF). The GOV is then multiplied by the VCF to obtain the GSV.

NOTE: The ASTM Measurement Tables are available in either PDF or hard copy at a cost of USD 60.00.

Who should conduct BLC Ullage Measurement/Gauging?

As advised in RB No. 64, Members should always appoint their own qualified and experienced surveyor to attend to protect their interests at all BLC loading and discharging events. The following attendance guideline, inclusive of vessel crew participation, should be followed:

- When an Owner’s surveyor has been appointed to facilitate a joint Shipper/Owner load port survey or Receiver/Owner disport survey together with a Shipper or Receiver surveyor, the crew should also attend throughout and sign the joint tank ullage report as measurement witnesses.

- If for some reason an Owner’s surveyor has not been appointed, the crew should attend cargo tank ullaging by Shipper’s or Receiver’s surveyor throughout as Owner’s representatives and sign the ullage report as measurement participants.

- Ship’s crew should normally only find it necessary to conduct ullaging by themselves in cases where no surveyor for any party has been appointed or is able to attend. Alternatively, the crew may have concerns as to the ullage gauging competence and/or integrity of the attending surveyor or surveyors. If the crew are in any doubt, they should always take, prepare and secure their own set of ullage measurements on owner’s behalf.

How should BLC Measurement/Tank Gauging be conducted?

The BLC tank shipboard processes are, as noted above, detailed in the API Guidelines, Chapter 17. They are outlined as below:

At Load Port

- The process commences with a pre-load vessel tank and cargo line inspection for issue of a Dry Certificate. If the BLC tanks are not dry of measurable cargo and/or tanks washings and a On Board Quantity (OBQ) remains, then – subject to agreement by all parties that the designated BLC may be Loaded on Top (LOT) – the OBQ must be calculated so that this amount may be deducted from the load completion TOV figure.

NOTE: The process of OBQ calculation is detailed in the API Guidelines at Chapter 17. 4. It is a process normally confined to the crude oil trades. - Pre-load enquiries to the shore terminal should also be made to establish whether any shore cargo line displacements have taken place and ascertain precisely what grade and the quantity of BLC is contained in the shore line.

NOTE: Shore line sampling is also a key evidence issue and Members are referred to RB No. 64, BLC Contamination and Sampling. - BLC tank gauging will be conducted on completion of loading. On older and smaller tankers, this will usually be done by the manual and open gauging method using flexible steel tapes with brass bobs attached. Newer and larger tankers are now usually fitted with closed system float type gauges which simply require the BLC ullage to be read off a deck mounted indicator.

NOTE: These processes are covered in detail by the API Guidelines at Chapter 17.2. - The vessel’s BLC tank calibration tables will then be entered and tank specific corrections for vessel list and trim will be applied to the tank ullages as read. The corrected ullages will then, collectively, provide the TOV as referred to above.

- The BLC observed temperature will also be ascertained by lowering thermometers with protective casings into the BLC tanks. The temperature readings will usually vary from top to bottom in each tank such that taking an average of three readings (top, middle and bottom) is considered as best industry practice.

- BLC Free Water (FW) dips (as shown on a brass bob smeared with water indicating paste) are also required to ascertain the depth and amount of FW at the bottom of each BLC tank. The total FW amount will be deducted from the TOV to provide the GOV and, after application of the VCF, the BLC’s GSV.

NOTE: The GSV is the ship’s figure and will not usually be allowed by the shipper and/or charterer to be entered on the BL, whether expressed in cu. metre volume or metric tonne weight. This presents an important and complex issue that will be discussed in an upcoming Risk Bulletin. - The GSV quantity, commonly referred to as the ‘ship’s figure’, should preferably be calculated and agreed on a joint party basis. The ship’s figure will then be compared with the shore tank load figure. The shore figure is usually the BLC load quantity figure provided by the BLC shipper for entry into the BL.

NOTE: There will always be some difference between the shore tank load quantity figure and the shipboard load figure. There are numerous reasons for this including ship and shore tank calibration inaccuracies, temperature and gauging inaccuracies, density measurement errors, etc. Differences can also arise due a tanker’s Vessel Experience Factor (VEF), as explained below. - The term VEF is explained in the API Guidelines at Chapter 17.9. In brief, the VEF is basically the historical difference between ship and shore tank figures for a specific tanker for a given period (usually the previous 10 loadings). It is a factor that indicates a tanker’s tank calibration error in relation to a full cargo. The global average VEF for tankers is reported to be in the region of – 0.2% to + 0.2% ship over shore.

NOTE: If a ship/shore quantity difference lies within a tanker’s historical 10 voyage VEF, then the difference should be considered as acceptable. If it does not, then all measurements and calculations – both ship and shore – should be carefully reviewed to assess whether any error or other cause has generated an inconsistent VEF.

At Discharge Port

- The next BLC tank gauging and calculation of GSV will take place immediately before commencement of discharge. The gauging and calculation process will be the same as at the load port, as described above. The ship’s load port GSV and ship’s disport GSV will then be compared to establish if any observed In Transit Loss (ITL) has occurred.

NOTE: There will always be some difference between the ship’s load port and disport GSV figures. Some of it may be due to ‘physical losses’, such as the evaporation of light BLC factions, and some of it may be due to ‘apparent losses’ due to ship tank ullage and temperature errors. The critical issue will then be what CTA terms and amount were agreed. If the CTA tolerance is exceeded, the cause or causes need to be carefully investigated for shortage claim defence purposes. - On completion of discharge, a joint inspection of the ship’s tanks is essential to obtain a Dry Certificate from consignees/receivers which confirms that all pumpable cargo has been discharged from the vessel.

- If the BLC cannot be pumped out to the Dry Certificate standard required, then the Remains on Board (ROB) quantity must be calculated. This is accomplished in the same manner as the measurement and calculation of OBQ. Such circumstances will likely lead to a shortage claim if the ROB and any other observed losses exceed the agreed CTA.

- Finally, if the BLC is pumped out to the standard required and a Dry Certificate is issued, this minimises but does not exclude a short delivery claim based on any comparative difference between the load port shore tank/shipper’s BL quantity figure and the discharge port shore tank reception/receiver’s figure in an amount which exceeds the agreed CTA.

NOTE: A shortage claim based on any difference between the load port and disport shore tank figures is, by reference to English law and some other common law jurisdictions, invalid, as the shipowner’s/carrier’s responsibility extends only from the time the BLC passes the ship’s rail at the cargo manifold during loading and the same when it leaves the manifold on discharging. Regrettably, there are numerous other jurisdictions that do not recognise the English/common law interpretation of the shipowner’s period of responsibility.

Conclusion and Takeaway

The complete elimination of BLC shortage claims is practically unattainable due to both technical issues and jurisdictional uncertainties relating to contract terms enforcement. This Risk Bulletin has focused on the technical aspects of the BLC measurement process which can greatly assist in the minimisation of shortage claims. The equally important contractual and legal aspects of BLC shortage loss prevention, some of which have been mentioned above, will be detailed further in an upcoming Risk Bulletin.

With respect to the BLC measurement process, there are numerous physical and human element factors that make it very difficult to accomplish with absolute accuracy. This problem has been recognised by the creation and industry acceptance of the 0.5% CTA. As such, the goal must always be for Members to ensure that no observed BLC shortage (whether ‘physical’ and/or ‘apparent’) exceeds the specifically agreed CTA in the CP and BL terms.

Attaining the required ‘claim minimisation’ goal requires meticulous attention by tanker owner Members and their crews to the BLC measurement process as detailed by the API MPMS Chapter 17, Guidelines for Marine Inspection. The application of these industry best practice standards will improve accuracy and will support the validity of all the measurement evidence obtained for both operational purposes and shortage claim defence requirements. Members are encouraged to share this Risk Bulletin with their tanker fleet managers (both technical and commercial), DPAs, masters and crews. Members should then ensure full ISM Code or NCVS SMS procedures-based implementation of the API Chapter 17 Guidelines, supported by subsequent SMS auditing to confirm full and effective implementation.