Introduction

The boarding and disembarkation of a ship’s pilot, often in challenging weather conditions, is a unique and hazardous exercise. The incidence of injury and fatalities during ship to pilot boat transfers is substantial. The cause is often due to pilot ladder and ancillary equipment failure and/or improper rigging by the ship’s crew. This Risk Bulletin looks at the hazards, the regulatory requirements and industry recommendations for making the pilot transfer process a smoother and safer exercise for all concerned.

Background

Internet research indicates that pilot transfer fatalities worldwide average about 2-3 each year and pilot transfer injuries – to varying degrees of severity – run far higher. Ships’ crew involved in rigging pilot ladders and accommodation ladders are also at risk of injury or falling overboard. The trauma, associated delays and costs arising out of such incidents and claims can be extremely high.

Members also need to understand that pilots have the right to decline to board vessels offering defective boarding arrangements. This can result in disruptive and costly delay. Pilots are also entitled to report defective boarding arrangements to Port State Control (PSC) authorities. In turn, this can lead to a full PSC inspection with the potential for further delay and financial losses.

Lessons Learned

Pilot ladder transfer fatalities, injuries, ‘near misses’ and their investigation are regularly reported by both flag state authorities and other interested parties. The causes are primarily related to pilot ladder condition and their rigging.

The International Marine Pilots Association (IMPA) conducts frequent global safety campaigns and surveys. The intention is to identify and highlight failures of compliance with SOLAS regulations relating to pilot ladder arrangements.

The IMPA 2020 campaign extended to six global regions and included returns from 6,394 pilot boarding’s. It reports that, of these returns, 5,620 vessels were compliant, and 774 vessels (12%) were non-compliant. The full details are contained in the campaign report and are worthy of careful reading.

Some disturbing examples of observed non-compliance are noted below:

- Ladder not secured properly at the maindeck.

- Ladder not fully in contact with ship’s hull due to hull protrusions.

- Broken or unequally spaced ladder steps.

- Steps not horizontal.

- Steps dirty and/or slippery.

- Handhold stanchions at top of ladder not properly secured.

- Inadequate lighting at night.

- No responsible officer in attendance and/or no VHF contact with bridge.

- No lifebuoy with self-igniting light and/or heaving line available.

The 774 vessels that were non-compliant presented a significant safety risk to a boarding or disembarking pilot. They were all reported to the appropriate authorities. The IMPA’s serious concerns were expressed their 2020 campaign report as follows:

“Sadly, the maritime industry repeatedly fails to implement its own agreed minimum standards. The adoption of IMO Resolutions is not “job done!” It is “job started!” All stakeholders should ensure that the recommendations and guidelines in Resolutions and Circulars are adhered to.”

The IMO conventions and resolutions referred to by the IMPA are explained below.

Pilot Boarding Arrangements and Regulatory Compliance

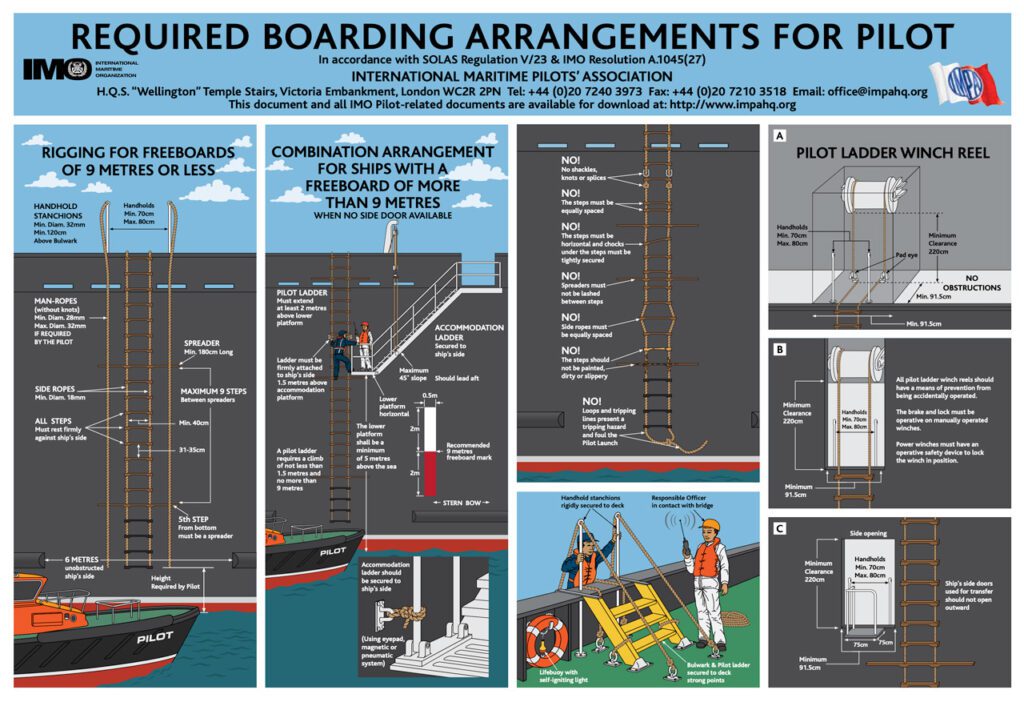

SOLAS Chap V Reg 23 and IMO Resolution A.1045 (27) and Resolution A.1108(29) provide the mandatory pilot boarding arrangements. This includes rigging pilot ladders (for a vessel with a freeboard of 9 m. or less) and rigging a combined pilot ladder and gangway (for a freeboard of 9 m. or more). A ready reference and visual summary of the aforesaid requirements is depicted in the International Marine Pilot’s Assoc. (IMPA) poster shown below.

The IMPA poster should be prominently displayed on board every vessel utilising pilot ladders for pilot, crew and other personnel transfers. Some of the key information it illustrates includes:

- Construction of a pilot ladder, including rope size and wood step dimensions and spacing.

- Requirement for wood spreaders – including spacing and minimum width – to prevent the ladder from twisting when being climbed.

- Details of man-ropes to be secured at each side of the pilot ladder.

- Details of steel post stanchion handholds to be secured to the maindeck and bulwarks at each side of the pilot ladder.

- Details of the support equipment required including a life ring with self-igniting light, a heaving line, bulwark steps and, very importantly, the attendance of a deck officer equipped with a VHF radio and appropriate PPE.

- If vessel freeboard is more than 9 m., such that a pilot and accommodation ladder combination is required, additional factors are:

- the accommodation ladder lower platform must face aft,

- the minimum 5 m. distance of the lower platform from the sea,

- the lower platform’s close proximity to the pilot ladder,

- the necessity to secure both the pilot and accommodation ladders to the ship’s side.

Pilot Ladder Construction, Marking and Certification

The construction, marking and certification of pilot ladders are detailed by SOLAS Chap 5 /23 and IMO Res. A.1045 (27). These regulations also permit the application ISO 799 – 1: 2019, Pilot Ladders Part 1 – design and specification, as an acceptable alternative standard. Some of the key requirements of SOLAS and ISO 799 -1: 2019 are that:

- Pilot ladders must be clearly marked/labelled as such, together with their length and number of rungs, on both the top and bottom steps.

- They are subject to SOLAS inspection as part of annual flag state Safety Equipment Certificate inspections.

- SOLAS requires that Pilot ladders over 30 months old (in use time) are required to undergo an independent strength test and the results must be marked on the ladder.

- Pilot ladders must not be use for any other purpose other than the embarkation and disembarkation of pilots and other personnel.

- They must always be kept clean, protected and in good repair.

- If any steps become broken during use, then not more than two replacement steps – which are not secured as original and may therefore only be considered as a temporary repair – may be fitted. Any such repairs must be made permanent at the earliest opportunity.

Pilot Ladder Transfers and the ISM Code

Members whose vessels are engaged in international trade will be aware that SOLAS Chapter 9, ISM Code, at Part A, para. 10.1, requires that vessel owners establish procedures to ensure that a ship is operated and maintained in conformity with all relevant rules, regulations and industry best practice. On board vessels in the domestic trade, there will be similar non-convention vessel standards (NCVS) which usually mirror the ISM Code obligations.

It follows that all Member vessels using the services of pilots and conducting pilot transfers must be provided with comprehensive ISM Code/NCVS procedures which cover all aspects of pilot transfer arrangements inclusive of pilot ladder specifications, rigging, maintenance, certification and crew training.

Members are referred to the websites and pages linked below to obtain further information and practical advice.

- International Maritime Pilots Association – “50 years promoting pilot safety”.

- Pilot Ladder Safety – “Do it right the first time”.

- ICS Shipping Industry Guidance on Pilot Transfer Arrangements – “Ensuring compliance with SOLAS”.

Members should also consider incorporating the ISM Code based Permit to Work (PtW) system to pre-use checking and rigging of pilot ladders and pilot ladder/gangway combinations. A useful sample of PtW Pilot Transfer checklist is available in CHIRP’s Maritime Feedback Newsletter, June 2022, at page 11. Its use will help to enhance pilot transfer safety and provide a written record that pilot ladder pre-use checking and rigging has been done correctly.

Conclusion and Takeaway

The risks of injury and death during pilot or other personnel transfers which require the use of pilot ladder, or a pilot and accommodation ladder combination, are significant. These risks can be minimised by ensuring the thoughtful improvement and on-going application of comprehensive ISM Code/NCVS pilot transfer arrangement procedures on board Member vessels.

Members are encouraged to share this Risk Bulletin and the links it contains with their ship managers, DPAs and Masters with a view to assessing and upgrading their current ISM Code/NCVS pilot transfer procedures.

The goal for every Member should be to make sure that none of their vessels or their crews ever fall within the IMPA’s reported 12% non-compliance rate with IMO or NCVS pilot ladder regulation and become a potential cause of injury or death during a pilot or personnel transfer operation.