Introduction

A ship capsize is a seafarer’s worst nightmare. These incidents are often due to inadequate ship stability caused by a sudden and unplanned rise in the ship’s Centre of Gravity (CoG). Tragic consequences include injury, death, pollution and total loss of ship and cargo. All ships are exposed to this potential danger but some ship types and trades are much more exposed than others. In particular, containerships and general cargo and multi-purpose ships carrying containers on deck – with a high ship CoG and low residual stability are in the instability high risk category.

This Risk Bulletin is intended to raise member awareness of the stability challenges faced by the master and crew of containerships, or other vessels that carry containers on deck. The specialist knowledge and vigilance required to keep these ships, their crew and cargo and the environment safe from instability harm are discussed below.

Background

In order to optimise their cargo capacity and revenue, containerships and other container carrying vessels are required to carry loaded containers stacked on deck. In turn, this high cargo weight positioning produces a relatively high but –if carefully managed – still tolerably safe CoG and residual stability on completion of loading. However, it does not take much to go wrong for this safe stability tolerance to be impacted and a very dangerous situation to develop.

Ship Transverse Stability Fundamentals

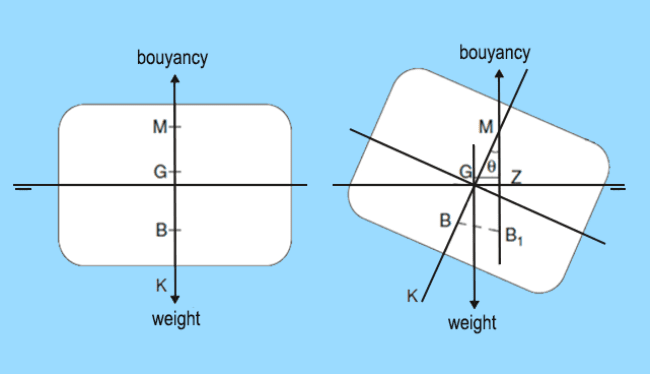

A vessel’s ability to stay upright and return to the upright, if heeled over by an external force, is based on the positional relationship between two points of force being Gravity (G) downwards and Buoyancy (B) upwards and one point of balance, the Metacentre (M), which are all shown in the diagrams below.

There are three types of ship equilibrium conditions that can occur. The first is positive and safe. The second is neutral and dangerous but, with care, can be rectified. The third is unstable and is often fatal. These conditions are described below.

1. Stable Equilibrium:

A stable equilibrium is achieved when the vertical position of the ship’s CoG (G) is lower than the position of the transverse metacenter (M). When the ship heels to an angle (shown as theta Ɵ), the center of buoyancy (B) shifts to B1. The lateral distance, or what is known as the Righting Lever (GZ), generated by the weight and buoyancy forces in this heeled condition, results in a counter rotating force known as the Righting Moment. It is this positive force that brings the vessel back to an upright position.

The position of M above G should be carefully noted in the diagram above. These safe positions and the distance GM is a critically important measure of positive ship stability.

2. Neutral Equilibrium:

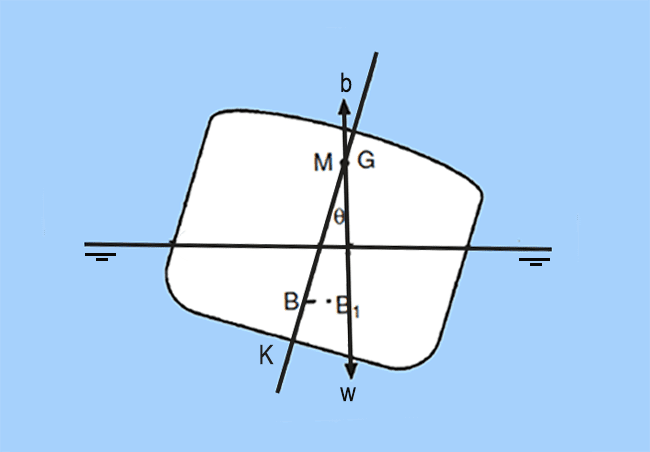

This is a dangerous stability situation for any ship. It occurs when the vertical position of G rises (perhaps during a ballast water exchange) and coincides with M. In this neutral GM condition, no GZ Righting Lever is generated and no Righting Moment can develop to bring the vessel upright. The vessel will therefore remain at what is known as an Angle of Loll. Action must therefore be taken to bring G down below M by first ballasting a DB tank on the low side. A Righting Moment will then develop as G lowers and brings the vessel back towards the upright.

3. Unstable Equilibrium:

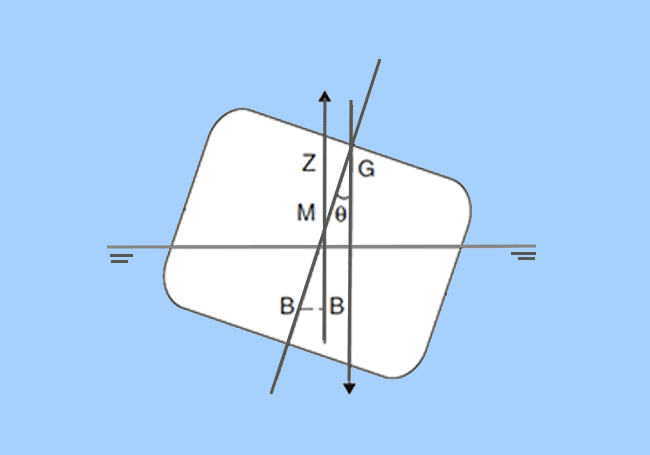

Instability occurs when the vertical position of G rises above M. The vessel then has a negative GM. The Righting Lever GZ is then also negative such that the Righting Moment will now act in reverse to increase the angle of heel. This will continue until the vessel’s underwater hull form and B possibly reaches a position of stable equilibrium. This must occur before the main deck edge becomes immersed at water level. If it does not, then the vessel will capsize.

Stability Regulations and Compliance – International Trade

The International Load Line Convention (LLC) 1966 (with its 1988 Protocol, as amended) and SOLAS both require that all vessels which are regulated by these Conventions (i.e. vessels over 500 GT and engaged in international trade) must carry adequate stability data (in the form of a stability booklet) to ensure their safe operation. The details are provided by IMO Resolution MSC.267(85), the International Code on Intact Stability (IS Code) 2008.

The IS Code 2008 applies to all vessels regulated by the LLC and SOLAS and which are 24 m. in length or over. It is divided into two sections. Part A is mandatory and Part B is recommended by the IMO to Flag State administrations.

Part A sets out the minimum stability criteria in relation to the required minimum Righting Lever (GZ) and the GM. It also provides the minimum criteria relating to a vessel’s ability to withstand beam rolling caused by severe sea waves and wind. This data is complex and is designed as a guidance to naval architects when designing ships and preparing their stability booklets (for Master and crew use) and to Flag States and Class (acting as Recognised Organisations) when approving stability booklets.

Part B contains advice intended to supplement Part A in relation to particular cases regarding the size or operation of vessels. This includes fishing vessels and barges. Importantly, it also includes an alternative and more rigorous set of stability criteria recommended for containerships over 100 m. in length as well as for “other cargo ships” designed “with considerable flare and water plane area”. Although not specifically stated in the IS Code, this alternative is no doubt intended to help reduce the dangers of Parametric Rolling which is described later.

Stability Regulations and Compliance – Domestic Trade

For vessels which operate in domestic trade, such that they are not regulated by the LLC or SOLAS, then the IS Code 2008 is not directly applicable. However, domestic trade vessels will be regulated by similar Non-Convention Vessel Standard (NCVS) national regulations. An example of this is the Indonesian NCVS, Chapter 6, Loadlines, which contains the full details of the stability data which must be carried on board a domestic trade vessel. Importantly, Chapter 6 makes specific reference to the IS Code 2008 as providing the underlying basis for NCVS stability standards, their implementation and regulatory compliance.

Stability Training and Competence

The STCW Convention (as amended) at Tables A-II/1 and A-II/2 sets out the minimum stability training and knowledge that a qualified ship master and deck officer must acquire and demonstrate to obtain a Certificate of Competence (COC). This requirement is supported by IMO Model Courses used by COC training organisations in all IMO member states. As such, the intent is there should be a uniform level of minimum IMO stipulated stability knowledge that all qualified Masters and deck officers can be presumed to have acquired.

The aforementioned training and knowledge at the STCW Table A-II/2 level for Masters and Chief Officers should be sufficient to deal with all aspects of ensuring a vessel’s safe stability, inclusive of the containership and container carrying vessel stability hazards discussed below. Despite this, stability accidents and losses continue to occur. The problem therefore seems to be that, in most cases, it is not a lack of seafarer knowledge which causes stability accidents. Instead, it appears to be the lack of consistent application of this knowledge and the exercise of due diligence.

Containership Stability Hazards and Avoidance

Containerships and cargo vessels carrying containers on deck are faced with five high profile stability hazards. They are described below, together with recommended loss prevention measures and further information links.

Hazard 1. Misdeclared weight of container and cargo; sometimes done intentionally by shippers to avoid full payment of freight or shippers’ ignorance of the impact on the carrying vessel’s stability and the associated dangers. This hazard has been reduced by SOLAS, Chap. VI, Reg. 2, para. 6 (in force 2016) and IMO’s MSC.1/Circ.1475 Guidelines on VGM of a Container Carrying Cargo . These rules require that before a container can be loaded on board a SOLAS regulated vessel (i.e. over 500 GT in international trade), the shipper must sign and provide a ‘Verified Actual Gross Mass of the Container’ (VGM) certificate to the Master.

Regrettably, the weight misdeclaration hazard has not been negated as the global enforcement of the SOLAS rules and IMO Guidelines by Flag and Port States is reported to be irregular. Furthermore, SOLAS Chap VI and MSC.1/Circ.1475 do not usually apply to domestic trade shippers and vessels. As a consequence, misdeclared container weights still present a significant and dangerous hazard in both the international and domestic container trades.

Avoidance 1: Awareness of the on-going misdeclared container weight hazard is the first line of defence for both containership masters and shore based stowage planners. Stevedores should be instructed to advise the master immediately if, during container handling and loading, they observe any containers that appear to be overweight or well in excess of their shipper declared weight. Any such containers should be re-weighed at the terminal and rejected if their weight is not – within reasonable tolerance – as declared.

Hazard 2. ‘Free Surface Effect’ (FSE) – due to bunker fuel and ballast tanks being left in a partially full or ‘slack’ condition and not full (to at least 98%) and ‘pressed up’. FSE causes a virtual but – in terms of effect – the very real rise of a ship’s CoG. If this hazard is not recognised and incorporated into the stability calculation, the instability outcome can be fatal.

Avoidance 2: A high level of awareness of FSE and close cooperation between the master and chief engineer in minimising the number of slack fuel and ballast tanks is essential. This is especially important on board containerships where the positive GM and residual stability in a fully loaded condition will normally be quite restricted. FSE must therefore always be minimised and never forgotten.

Hazard 3. Sudden Rise in Ship’s CoG – caused by lifting a heavy container using a ship’s crane which instantly transfers the weight and CoG of the container to the top of the crane jib. In turn, this will suddenly raise the combined CoG of the ship and her cargo. If this occurs during the final stages of loading containers on deck, such that the ship’s CoG is already quite high and the GM small, then a sudden and additional rise of the ship’s CoG and a resulting neutral or negative GM can cause a heavy list or even a capsize.

Avoidance 3: Again, a high level of stability awareness is required to avoid such situations. This must include the requirement that the calculation of stability must take into consideration not only a ship’s final departure stability but also her stability during all stages of loading and discharging operations and the delivery voyage.

Hazard 4. Synchronous Rolling – is referred to in the IS Code 2008 as resonant rolling. It is also explained in the IMO’s Revised Guidance to Masters for Avoiding Dangerous Situations in Adverse Weather and Sea Conditions, MSC.1/Circ.1228. This phenomenon is caused by the ship’s roll period (the time of one complete roll cycle) becoming resonant/matched to the ocean wave swell period. It is a hazard to which high CoG containerships can be exposed to, particularly if the engine has been stopped in heavy seas and swell. If this occurs, a ‘dead ship’ will naturally move to a position beam on the wind and swell. As matching ship roll period and wave period resonance develops, the ship will heel over and develop a heavy list. A container carrying vessel may then be heeled even further by wind pressure and swell action to a point of negative instability.

A recent example of the synchronous rolling hazard described above is the ‘APL ENGLAND’, a CMA CGM containership that recently lost 40 containers off the coast of Australia when stopped due to a main engine breakdown of only a brief duration.

Avoidance 4. There are three methods of overcoming synchronous rolling which have proved to be effective.

- Lowering the ship’s CoG and increase its GM by taking water ballast on board into DB tanks. This will change the vessel’s roll period so that it no longer matches that of the sea and swell.

- Altering the ship’s course heading so as to introduce a yawing effect and change the approaching wave frequencies.

- Altering the ship’s speed so that ship/wave synchronism is defeated.

Hazard 5. Parametric Rolling – is a highly technical and not yet fully understood phenomenon which is explained in the IMO’s Revised Guidance referred to above. It has occurred on a number of occasions on board Post Panamax vessels built with large bow and stern flares and flat transoms. It is most likely to occur when a vessel of the above description is underway in head sea and pitching heavily. A combination of ship and wave hydrodynamic forces are then developed which generate heavy rolling oscillations. Rolling up to an angle of 45º has been experienced (well beyond Class limits of 35º for container securing gear) with the loss of up to 400 containers during a single incident.

Avoidance 5. Members who own or operate Post Panamax container vessels or vessels with similar hull form characteristics should ensure that their ship managers and masters are provided with a copy of the aforesaid IMO Revised Guidance. Members should also ascertain whether or not the stability booklets for any such vessels have been prepared by reference to the updated and alternative criteria for container ships over 100 m. in length as recommended by Part B of the IS Code 2008.

Conclusion and Takeaway

Ship stability is a critical ship, crew and cargo safety issue. As a consequence, ship stability requirements have been comprehensively regulated and master and deck officer STCW training standards ensure competence. However, despite what appears to be ample regulatory and training measures, ship stability incidents and losses continue to occur. The question must then be as to what can be done to prevent recurrence?

One answer may lie in raising shipboard awareness of the dangers of ship instability and the precautions required. The goal being to encourage and motivate the consistent application of master and deck officer stability knowledge to a vessel’s operation on a daily and, when necessary, more frequent basis. This is of particular importance on board containerships and vessels carrying containers where the range of residual safe stability is often significantly less than on board ‘low cargo’ carrying bulk carriers and tankers.

In summary, MMIA recommends three ways in which Members can raise shipboard safe stability awareness and minimise losses due to ship instability.

- Ensure that your ship managers and ship masters are provided with copies of this Risk Bulletin No. 30 and the information links it contains.

- Ensure that each containership and/or container carrying vessel in your fleet is provided with an ISM Code SMS Manual which contains comprehensive procedures for frequent ship stability assessment and maintenance. These procedures should include specific references to the ship’s stability booklet as well as to the applicable regulation (LLC and SOLAS or NCVS rules, as appropriate) and IMO Guidance advice referred to in this Risk Bulletin.

- Ensure that the annual internal SMS audit of every vessel in your fleet includes a specific audit of the stability maintenance and reporting procedures which is completed by an auditor qualified to STCW Table A-II/2 stability training and competence standards.